-

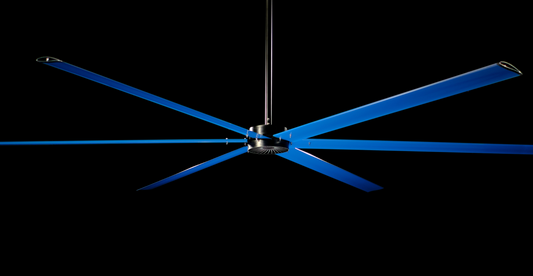

AirVolution

Precio habitual $0.00 USDPrecio habitualPrecio unitario por

What Are Industrial Ceiling Fans?

Industrial ceiling fans are designed to meet the rigorous demands of industrial settings. Unlike residential ceiling fans, these powerhouses are equipped with powerful motors to facilitate the movement of large volumes of air, ensuring a safer work environment by providing high-volume airflow. Tailored for use in commercial spaces like warehouses, factories, and outdoor spaces, they offer both robust construction and reliable performance.

These fans have metal blades and direct drive systems that contribute to both their durability and efficiency, leading to significant energy savings by reducing a facility’s energy consumption. Their ability to cover a vast area without occupying floor space makes them ideal additions to any industrial space. Additionally, features like remote controls enhance convenience, allowing for easy adjustments of fan speed to optimize air movement.

With the capacity to operate at various ceiling heights, industrial ceiling fans can be installed to promote safe operation and contribute to the comfort and productivity in commercial environments. Their purposeful design translates into an indispensable tool for maintaining airflow, regulating temperature, and ultimately cutting down on energy costs while providing a compelling solution for air circulation challenges in any industrial setting.

Why Choose MacroAir?

Our journey began in the early 1990s, driven by a problem-solving approach and a passion for innovation. The Boyd family pioneered the world's first high-volume, low-speed (HVLS) fan, transforming how air moves in industrial settings. Today, MacroAir fans stand as a testament to our commitment to engineering excellence. Proudly assembled in the USA and installed worldwide, our fans deliver unparalleled energy efficiency and airflow. We are a family-owned and operated company, led by Eddie Boyd and his daughters, ensuring that our values of innovation, quality, and customer satisfaction remain at the forefront of everything we do.

Benefits of Using Industrial Ceiling Fans

Industrial ceiling fans are more than just an accessory for industrial spaces; they are a vital component in creating an efficient, productive, and comfortable environment. They are designed to tackle the unique challenges inherent in commercial and outdoor settings where standard ceiling fans simply will not suffice.

Enhancing Airflow

In vast industrial spaces, maintaining consistent airflow can be a challenge. Industrial ceiling fans excel at circulating air on a grand scale, dispersing it evenly throughout the area. They are specifically engineered to move large volumes of air, which helps in ventilating the space and can prove instrumental in clearing out pollutants and airborne debris – factors that can impact both product quality and workers' health. The improved airflow also prevents the formation of damp, stagnant areas that could contribute to the growth of mold or mildew.

Improving Comfort Levels

The comfort of employees in industrial settings is paramount and can directly influence productivity. Industrial ceiling fans contribute significantly to a more comfortable work environment. During hot weather, the breeze generated by these fans helps in evaporative cooling of the skin, providing relief from the heat. Conversely, during colder months, they can be used in reverse to circulate warm air trapped at the ceiling level downward. This versatile temperature regulation capability ensures a comfortable setting year-round.

Energy Efficiency

High energy bills are a concern for any industrial operation. Industrial ceiling fans are part of the solution, contributing to energy savings by improving the efficacy of heating and cooling systems. Since the fans disperse air more efficiently, HVAC systems don't have to work as hard, which leads to a reduction in energy consumption. This enhanced energy efficiency not only lowers operational costs but also has a positive environmental impact.

Year-Round Usability

Perhaps one of the most compelling advantages of industrial ceiling fans is their applicability throughout all seasons. In summer, the fans offer a cooling effect, while in winter, they can be used to push warm air down from the ceiling and reduce the strain on heating systems. This dual functionality ensures that the investment in industrial ceiling fans pays off throughout the year – a cost-effective feature that enhances the appeal of these high-functioning devices.

By adopting industrial ceiling fans, a business benefits from improved air quality, a more comfortable work setting, increased energy savings, and a versatile tool that adapts to seasonal requirements, making them an indispensable element of an effective industrial environment.

Enhancing Airflow

Enhancing Airflow in Industrial and Commercial Spaces

The inclusion of Industrial Ceiling Fans in commercial and industrial settings is a game-changer for air movement and environmental comfort. With their powerful motors and high-volume airflow, these fans are equipped to handle the vast volumes of air necessary for maintaining a safer work environment.

Key Advantages:

- Energy Savings: These ceiling fans are specifically designed to cut down energy consumption, leading to significant energy savings.

- Space Maximization: By occupying minimal floor space, industrial ceiling fans optimize the available industrial space, a valuable feature for places with limited area.

Speed and Efficiency:

Industrial fans come with metal blades and robust construction, ensuring reliable performance and the capacity to move large amounts of air efficiently. Such efficiency is critical for maintaining air quality and temperature regulation, especially in settings with high ceiling heights.

Operational Safety:

Safe operation is paramount. Enhanced safety features, including direct drive mechanisms and remote controls, allow for both safer handling and operation, preventing accidents and ensuring consistent performance.

Conclusion:

Industrial Ceiling Fans present an undeniable solution to enhance airflow, reduce energy costs, and promote a comfortable, safe working environment in both industrial and outdoor spaces.

Improving Comfort Levels

Improving comfort levels in industrial and commercial settings is paramount for productivity and safety. Industrial ceiling fans are a cornerstone solution, significantly enhancing air movement and regulating temperatures.

Key Points:

- High-Volume Airflow: Industrial fans produce a high volume of air, ensuring consistent air movement even in spaces with high ceiling height.

- Energy Savings: By optimizing energy consumption, these fans contribute to noticeable energy savings.

- Safer Work Environment: A well-ventilated space is crucial for employee health, reducing the risk of airborne contaminants.

Features of MacroAir Industrial Ceiling Fans:

- Powerful Motors: Engineered for performance, the powerful motors maintain relentless airflow.

- Metal Blades: Sturdy metal blades withstand rigorous use, exemplifying robust construction.

- Floor Space: These ceiling-mounted fans free up valuable floor space in the industrial space.

- Remote Controls: User-friendly remote controls make adjustments convenient, ensuring safe operation.

- Direct Drive: Direct drive mechanisms offer reliable performance with minimal maintenance.

Investing in industrial ceiling fans leads to a more comfortable and productive workspace, underscoring the importance of efficient air circulation in maintaining a positive work environment.

Energy Efficiency

Energy efficiency is a critical aspect of managing any industrial setting, where minimizing energy consumption while maximizing performance is paramount. Industrial ceiling fans are pivotal in achieving this balance, offering significant energy savings. With high-volume airflow capabilities, these fans can effectively circulate large volumes of air, ensuring a comfortable and safer work environment.

Key features that contribute to the energy efficiency of industrial ceiling fans include powerful motors, direct drive systems, and robust construction. Metal blades, designed for longevity and maximum air movement, also play a role in enhancing energy efficiency. These features combined lead to less energy being required to maintain optimal temperatures and airflow within the industrial space.

In addition, the strategic use of ceiling fans can reduce the reliance on HVAC systems, which are often much more energy-intensive. By promoting air movement, industrial ceiling fans help regulate temperatures without the excessive use of additional cooling or heating resources.

Table Summary:

tilizing industrial ceiling fans is an intelligent choice for any industrial or commercial setting looking to improve energy efficiency and create a more cost-effective operational environment.

Year-Round Usability

When it comes to year-round usability, industrial ceiling fans are unparalleled in their versatility. These powerful devices aren't just suitable for the hot months; they provide a wide range of benefits all year long.

During warmer seasons, industrial ceiling fans generate high-volume airflow, which significantly improves the comfort level in industrial settings. The robust construction of these fans, complete with their metal blades and powerful motors, means they can move massive volumes of air with ease, offering much-needed cooling in vast spaces.

As temperatures drop, their utility doesn't wane. Heat tends to rise and can become trapped at ceiling height, especially in spaces with high roofs. Industrial ceiling fans are designed to recirculate warm air back to the ground level, ensuring a more uniform temperature distribution. This air circulation helps to maintain a safer work environment and contributes to energy savings by reducing the workload on heating systems.

Furthermore, with features such as direct drive and remote controls, they guarantee safe operation and effortless adjustment throughout the year. The impact on energy consumption is notable—by optimizing the temperature year-round, these fans support sustainable energy practices leading to substantial energy savings.

In summary, industrial ceiling fans are an indispensable tool for maintaining comfort and energy efficiency in commercial settings, regardless of the season.

Key Buying Considerations

When investing in industrial ceiling fans, there are several pivotal factors to consider ensuring that you choose the right solution for your industrial space. It is not merely about the air it moves; it is about considering how it integrates into the operational efficiency and safety of your workplace. From the blade span to noise levels, each attribute plays a key role in the effectiveness and appropriateness of the fan for your setting. Below are some essential buying considerations that can make a significant impact on your decision.

Size and Blade Span

The size of your industrial ceiling fan is critical and should be directly proportionate to the size of your space. The blade span, in particular, determines the amount of air movement the fan can provide. Large blades can move air in vast volumes, creating that high-volume airflow necessary for maintaining a comfortable temperature and air quality. When choosing a fan:

- Measure your floor space and ceiling height.

- Opt for larger blade spans for larger areas to ensure efficient air circulation.

- Ensure that the fan fits comfortably within the space without hindering operations or posing a risk to structures and machinery.

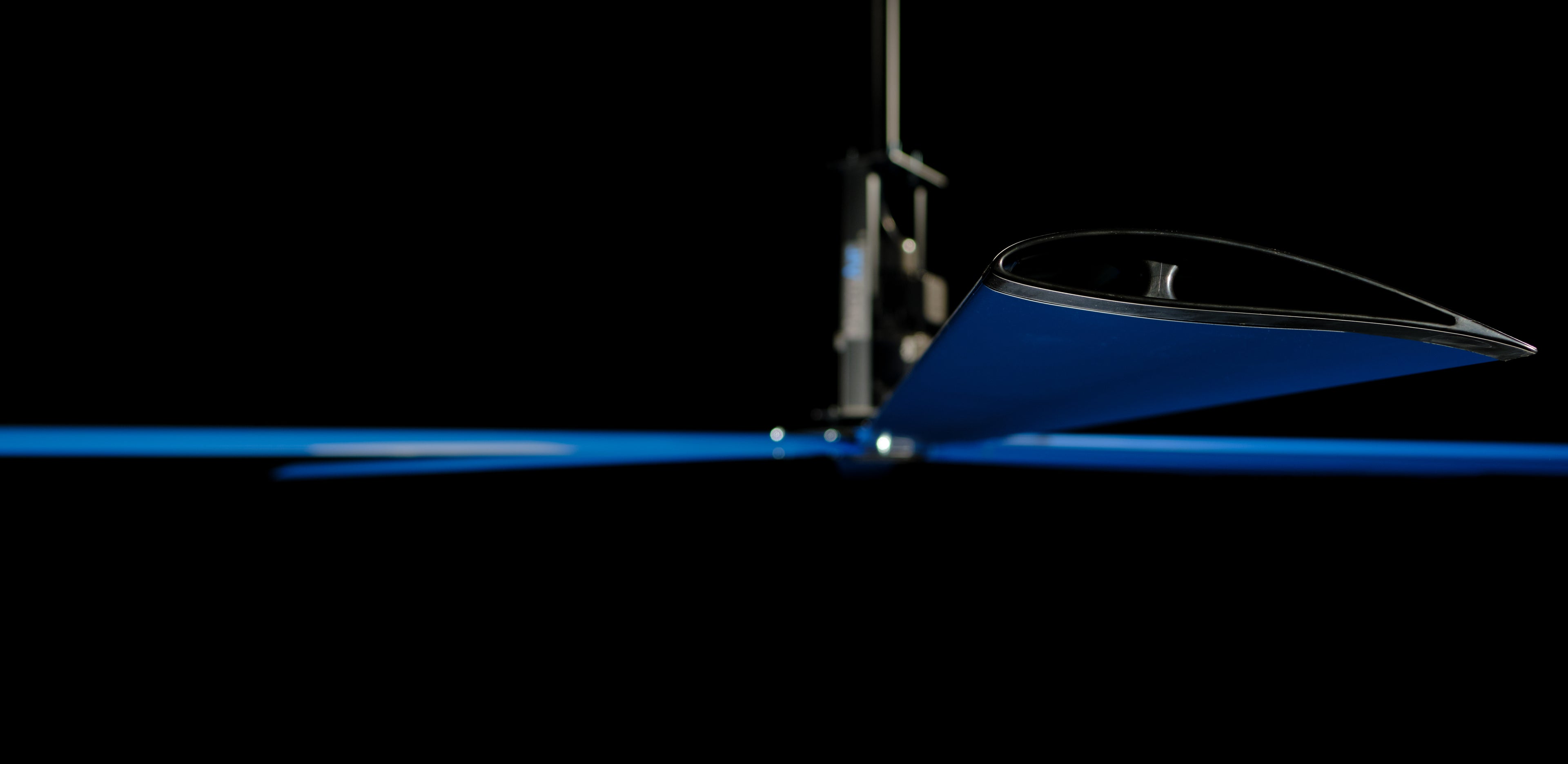

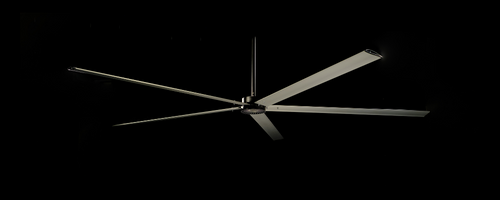

Style and Aesthetics

While the primary focus for industrial fans is function, form doesn't have to take a backseat. Nowadays, you can find industrial ceiling fans that blend seamlessly with your facility's aesthetics. Select fans with:

- A finish that complements your industrial setting.

- A design that supports your brand image and workplace ethos.

- A stylish yet robust construction that looks good while promising durability.

Control Options

Ease of use and functionality are essential for maintaining productivity and safety in an industrial setting. Consider industrial ceiling fans with a range of control options which include:

- Wall-mounted control units for easy access.

- Remote controls for operation from various points in your industrial space.

- Variable speed controls for precise airflow management, allowing you to adapt to different conditions with ease.

Noise Levels

In an industrial setting, minimizing additional noise can contribute to a safer and more focused work environment. Look for industrial ceiling fans that:

- Have precise engineering to reduce operational noise.

- Use direct drive motors that are typically quieter than belt-driven systems.

- Offer noise specifications—ensure they are within acceptable levels for your work environment.

Remember, choosing the right industrial ceiling fan isn't just about the immediate cooling effect—it's about integrating a long-term, energy-efficient, and safe solution into your daily operations.

Installation Guidelines

When outfitting an industrial space with ceiling fans, proper installation is key to maximizing efficiency, safety, and performance. Adhere to the following guidelines to ensure that your industrial ceiling fans are installed correctly:

- Consult the Manual: Always begin by consulting the manufacturer's installation manual for specific instructions pertinent to the model you have selected.

- Professional Installation: Due to their size and the complexities involved, industrial ceiling fans should be installed by qualified professionals to guarantee safe operation and compliance with local building codes.

- Inspect Components: Before installation, inspect all components for any damage incurred during shipping. This is crucial for safe operation.

- Correct Tools: Ensure you have the correct tools and equipment on hand. Industrial fan installations may require special equipment such as lifts or scaffolding to reach high ceilings.

- Ceiling Strength: Verify that the ceiling structure can support the weight of the fan. This may require reinforcement of the existing ceiling structure.

- Balance and Secure: Properly balance the fan to avoid wobbling and ensure all attachments are securely tightened to prevent future loosening.

- Safety Measures: Implement adequate safety measures to protect workers during installation. This might include locking out electrical circuits to avoid accidental energizing.

By adhering to these installation guidelines, you can help pave the way for your industrial ceiling fans to deliver reliable performance, energy savings, and enhanced air movement for years to come.

Site Assessment

Before the first screw is turned or the first bracket is mounted, a thorough site assessment is essential. It ensures that the industrial ceiling fans are apt for your industrial setting or outdoor spaces. Consider the following:

- Ceiling Height: Measure the height of the ceiling to determine the size of the fan needed and to confirm that there is sufficient clearance for safe operation.

- Floor Space: Assess the floor space and layout to decide the number and placement of fans for optimal air movement.

- Ambient Conditions: Consider factors such as temperature, humidity, and the presence of airborne particles, which could influence the type of fan best suited to your environment.

- Power Sources: Identify accessible power sources and any potential obstacles to running electrical wiring.

- Obstructions: Take note of any existing fixtures, machines, or structural elements that could interfere with fan installation or operation.

Mounting Options

The choice of mounting options is dictated by factors such as the industrial space itself and the desired volumes of air movement. Common mounting options include:

- Standard Downrod Mount: Ideal for spaces with high ceilings, allowing fans to hang at an effective height for air circulation.

- Flush Mount: Best for spaces with lower ceiling heights, flush mounts secure the fan close to the ceiling, optimizing floor-to-ceiling space.

- Angled Mount: For ceilings with a slope, angled mounts allow fans to hang level to the floor, ensuring even air distribution.

Ensure that your chosen mounting option aligns with the structure of your space to facilitate a proper and safe installation.

Electrical Requirements

The successful operation of industrial ceiling fans hinges on meeting their electrical requirements. Here are the key considerations:

- Voltage and Amperage: Confirm the fan's voltage and amperage requirements match your facility's electrical capacity.

- Dedicated Circuits: To avoid overloads, it may be necessary to provide a dedicated circuit for each fan.

- Grounding: Proper grounding is essential for safety and to protect against electrical surges or faults.

- Remote Controls: If your industrial ceiling fans come with remote controls, make sure to factor in the electrical needs for these devices.

Before any work begins, consult with a licensed electrician to ensure all electrical requirements are met and are compliant with electrical codes for a safe and energy-efficient installation.

Maintenance Tips

Industrial ceiling fans are robust workhorses designed for indoor and outdoor spaces within commercial and industrial settings, delivering high-volume airflow. However, to maintain their efficacy and longevity, regular maintenance is a key factor in preserving a safer work environment and optimal air movement. Adherence to maintenance protocols can also contribute to significant energy savings.

Regular Cleaning

First and foremost, keeping your industrial ceiling fans clean is vital. Dirt and dust accumulation on fan blades can lead to imbalance and reduced performance. For efficient operation, ensure the following:

- Wipe the fan blades periodically with an appropriate cleaning solution.

- Check for debris on metal blades and in motor casings.

- Ensure the cleaning regimen is compatible with the materials of your fan.

Regular cleaning maintains the fan's aesthetic and functional aspects, allowing it to move the desired volumes of air without additional strain on its motor.

Optimal Directional Usage

Understanding and utilizing the fan's directionality can bolster the efficiency of industrial ceiling fans, especially given the ceiling height of your industrial space:

- Summer Setting: Blades should rotate counter-clockwise to push cool air down. This creates a wind-chill effect, making the space feel cooler without lowering the temperature.

- Winter Setting: During colder months, switch the blade direction to clockwise to redistribute warm air trapped near the ceiling back into the living space, reducing the burden on heating systems.

Implement these directional settings through remote controls or a manual switch on the fan housing, depending on your fan's design, to capitalize on the distinct climate control advantages across varying seasons.

What Size Industrial Ceiling Fan Do I Need

Choosing the right size for an Industrial Ceiling Fan is essential for maximum efficiency in any commercial or industrial setting. The size of the fan should be proportional to the size of the space to ensure a widespread air movement and create a safer work environment. Factors influencing the size include the ceiling height, the area's square footage, and the specific needs of the industrial space, such as heat load and type of activity. Incorrect sizing could either lead to ineffective air circulation or an unnecessary increase in energy consumption. When selecting your industrial ceiling fan, keep in mind that larger diameters provide high-volume airflow that covers a more expansive area, reducing the number of fans required and further saving floor space.

8 Ft Industrial Ceiling Fan

An 8 Ft Industrial Ceiling Fan is suitable for spaces with modest square footage. The powerful motors of these fans provide a substantial amount of air movement that is perfect for smaller work areas, retail spaces, or outdoor spaces that require circulation. Metal blades ensure a steady stream of air and a direct drive system offers safe operation. Despite their smaller size, 8 Ft fans can make a tremendous difference in air circulation and contribute to significant energy savings by reducing the reliance on heating, ventilation, and air conditioning systems.

10 Ft Industrial Ceiling Fan

For a slightly larger industrial space, a 10 Ft Industrial Ceiling Fan hits the sweet spot between coverage and energy efficiency. The additional blade span allows for more extensive air distribution, ideal for medium-sized commercial settings. These fans can move substantial volumes of air, ensuring that every corner of your industrial setting maintains consistent temperature levels. The energy savings in heating and cooling due to the efficient circulation can often pay for the cost of the fan over time.

12 Ft Industrial Ceiling Fan

When dealing with ceiling heights and industrial areas where ample floor space is a concern, a 12 Ft Industrial Ceiling Fan is an excellent choice. Its robust construction and ability to displace large volumes of air make it ideal for keeping larger spaces cool and also in assisting with overall ventilation. The fan's reach ensures that work areas remain safe and comfortable for employees, helping to maintain productivity even in more extensive commercial settings.

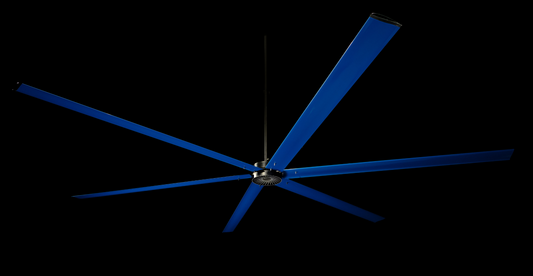

14 Ft and Bigger Industrial Ceiling Fan

For the ultimate in air movement within vast industrial spaces, nothing beats a 14 Ft or bigger Industrial Ceiling Fan. These oversized fans are engineered to provide a significant amount of airflow, appropriate for the largest industrial settings or outdoor areas. The sheer size of these fans translates to enormous energy savings as they are capable of replacing several smaller units. With remote controls for convenience and metal blades for long-term reliability, these industrial behemoths offer consistent, efficient performance, ensuring that maintaining a stable and comfortable environment is effortlessly within reach, regardless of the size of your industrial space.

Experience the MacroAir Difference

At MacroAir, we don't just manufacture fans—we engineer solutions that enhance environments, improve efficiency, and elevate comfort. Our dedication to innovative engineering, backed by decades of experience, ensures that you receive the best in industrial airflow technology. Whether you're upgrading your current setup or installing a fan for the first time, MacroAir's industrial ceiling fans are the ultimate choice for transforming your space.