Because airplane hangars often have concrete floors, they are susceptible to moisture issues....

Winglets: Help or Hindrance to HVLS Fan Performance?

High volume, low speed (HVLS) fans are becoming increasingly popular in warehouse and production facilities because of their ability to move large amounts of air creating a quiet, gentle breeze. In response to this, manufacturers are offering upgrades and additions to the standard motor and blades aimed at enhancing fan performance. One of the most common features is the “winglet” or curved end cap. However, when winglets are added to HVLS fans, it does little to overall performance and actually increases the torque on the blade, which causes the motor to work harder.

Winglets on airplanes are meant to help reduce drag and increase airflow efficiency. If a winglet blade benefits a plane, does it help HVLS fans? Through the tests that were used in Engineering Manager Michael Danielsson’s study in Consulting-Specifying Engineer, winglets actually increase the torque of the fan so much that it causes the motor to work harder than necessary to move the air caught by its blades. HVLS fans were made to push large columns of air down to the floor and back up to the ceiling, which is done in a continuous seamless motion by a fan without winglets. When a winglet is put on the tip of the fan blade, the winglet tries to change the direction of the air too quickly, making the fan work harder and creating inefficiency.

MacroAir fan blades are not manufactured with winglets, nor do we offer them as an upgrade. For some applications, like planes, winglets are a benefit, but we’ve found that HVLS fans are more efficient without winglets. HVLS fans on their own will provide a number of benefits to your facility or operation, including the following:

Reduced Energy Use

Since HVLS fans operate at a lower speed than traditional ceiling fans, they use less power. For large areas, there is much less energy needed to move the air, and as the inertia picks up, momentum is created. Studies have shown that these powerful fans use the same amount of energy as keeping only three or four light bulbs lit throughout the day.

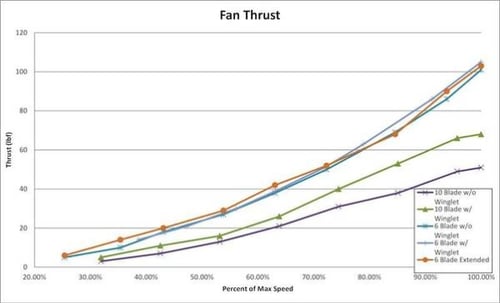

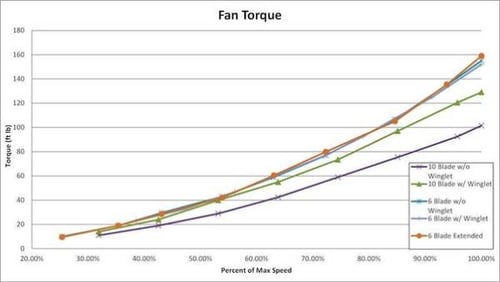

Figures 1 and 2 show MacroAir measurements of the thrust and torque of five different 24-ft HVLS fans—with and without winglets—at 25% to 100% of the fans’ maximum speeds.

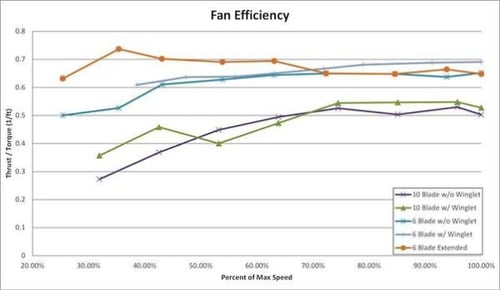

To determine the overall efficiency of a HVLS fan MacroAir determined the ratio of the thrust to the torque (see Figure 3).

With reduced energy, HVLS fans increase the thermostat temperature of any facility without affecting the comfort of the room. Studies have shown facilities can turn up the air conditioning thermostat by 4 degrees, and still get the same cooling effect as an HVAC system complemented with an HVLS fan.

Running in Reverse

MacroAir HVLS fans were the first HVLS fans to have the ability to run in a forward and reverse direction. This allows for massive savings on heating costs throughout the cooler months. In most buildings, the heating system is mounted above the workplace to create more space. Using a traditional ceiling fan in a forward motion leaves portions of heated air near the ceiling untouched, which is extremely inefficient. Since MacroAir HVLS fans allow building owners to run the blades in reverse, hot air from the ceiling areas can be pushed down toward the workspace for equal distribution. For a multi-level workspace, this also improves comfort level, as the workers higher toward the ceiling will no longer feel warmer than the workers down below. Improving the comfort of the workspace allows workers to feel better during their shifts, which improves productivity.

Additional Benefits

One of the challenges of a traditional HVAC system is that one must constantly adjust the thermostat for a comfortable temperature and to reduce the humidity in a facility. In the summer months, opening extra windows often isn’t enough if a breeze isn’t present, while in the winter when keeping the doors open just isn’t an option, excess heat may be building up. Humidity is another damaging factor in many work environments. Some products may react with excess moisture, food may become damaged, and it may even cause workers to become sick over time.

HVLS fans mix the incoming air with humid air to keep the environment fresh. The movement of the large fan blades and the gentle breeze that’s produced can also prevent bugs and birds from invading the space. Additionally, HVLS fans can eliminate the need for complex ductwork to maintain proper ventilation.

To learn more about the benefits of MacroAir HVLS fans, click here.