High volume, low speed (HVLS) fans are becoming increasingly popular in warehouse and production...

Solve Moisture Issues in Airplane Hangars

Because airplane hangars often have concrete floors, they are susceptible to moisture issues. Condensation can cause Sweating Slab Syndrome. These moisture issues are prevalent in humid climates, particularly in the fall and spring seasons.

When night comes and the temperature drops, the airplane hangar and everything inside it cools down. The next day the large doors are opened and warm, humid air floods into the space. The humidity level in the hangar continues to increase to match the outside humidity levels. Now the warm air, heavy laden with moisture, will look to deposit that water on surfaces that are at or below dew point. Concrete floors typically stay cool for a while, which is why they are particularly susceptible to Sweating Slab Syndrome.

Condensation’s Impact on Airplane Hangars

In aviation, wet floors create a frustrating and potentially dangerous condition for pushback tugs. When the floor is wet, pushback tugs become ineffective because they can’t gain traction. The situation can become dangerous if the tug tries to brake and skids instead – creating potential for injury and equipment damage.

Condensation isn’t limited to concrete slabs though. Any metal surface – the plane, the building structure, metal racking, or any object at or below dew point will experience the effects of condensation. Ongoing condensation issues lead to product degradation and additional maintenance requirements.

HVLS Fans Eliminate Sweating Slab Syndrome

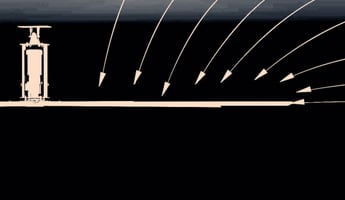

Due to their size and usage, installing an air conditioner or dehumidifier in an airplane hangar isn’t always feasible. High Volume, Low Speed fans provide an economic solution for the condensation issue by generating large columns of air that thoroughly mix the air. This homogenizes the air, equally dispersing the water vapor, thereby minimizing moisture deposits.

Additional HVLS Fan Benefits

In addition to solving the condensation issue, HVLS fans deliver a complete climate control solution. Running an HVLS fan in the forward direction will deliver a cooling breeze that drops the effective temperature by 8°F or more. During the winter, running an HVLS fan in the reverse direction brings the warm air trapped at the ceiling down to floor level. The dual functionality of HVLS fans maintains a comfortable environment for those working inside airplane hangars.

Installing HVLS in airplane hangars mitigates condensation issues, prolongs product life, and delivers a year-round climate control situation. Find out more by visiting our website today.